Professional Design & Manufacture Service

MSI is the leading provider of Design & Manufacture Service for major IPC company in Taiwan as well as worldwide famous Valued Added Reseller & System Integrator. Through intimate customer cooperation, and combining innovative technologies and industry leading architecture, MSI helps our OEM/ODM partners bring better products to market faster and more economically.

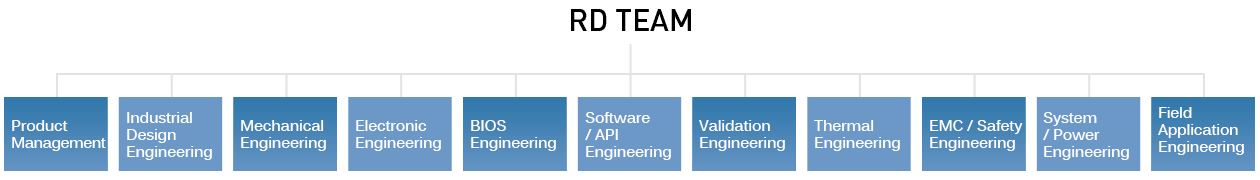

MSI Development Capability

Resource

| Product Management | Your dedicate windows for project management from project kick off to mess production. |

|---|---|

| Industrial Design Engineering | Able to through your desires, needs, motivations, and contexts to create suitable ID you need. |

| Mechanical Engineering | Solid design experience for retail POS, semi-rugged tablet, industrial application. |

| Electronic Engineering | Experience high speed bus design, layout, with reliable design philosophy for best MTBF performance. |

| BIOS Engineering | Module design, Legacy design , customized design to maximized product feature and performance. |

| Software/API Engineering | Create API for better communication and optimize software integration. |

| Validation Engineering | High investment of validation facility and compromised SOP execution. |

| Thermal Engineering | Thermal simulation for best thermal design to maximized thermal solution. |

| EMC/Safety Engineering | Design for more EMC/ESD margin to meet industrial requirement. |

| System/Power Engineering | Key Part Management , Power unit design, validation, and selection. |

| Field Application Engineering | Sustain technical service and ECN, EOL process. |

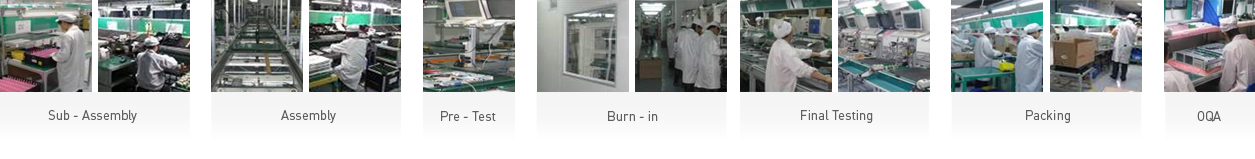

Manufacture Capability

All activity are located in same floor for best production management & quality control.

SMT Process

Surface Mounting Technology (Implement various AOI (Automatic Optical Inspection ) station to achieve our high quality standard.)

DIP Process

Dual in-line Package Skilled reflow process for RoHS components to ensure high reliability in the field

System Assembly Process

Stress on-line burn in process to stop early failure unit before shipment.

Capacity

Estimate Monthly capacity : 42120 sets

6 burn in rooms. Each burn in room allow 50 sets. Normal burn in criteria: 4 hrs with 40˚C.

Monthly capacity: 24 hrs/ 4hrs * 6 rooms * 50 sets * 26 days = 46800 sets By 90% utilization rate, it will be 42120 sets.

Certificate

(MSI was established with the business concept of "Excellent Product, Superior Quality, Perfect Service, & Customer Satisfaction“ with following certificate)

ISO9001:2008

ISO140001:2004

IECQ Certificate of Conformity

OHSAS 18000:2007

Quality System

- Equipment Calibration

- Quality system & internal audit

- Quality cost management

- Quality training

- Document control

- New supplier qualification

- Supplier audit

- SCAR management

- Component quality

- CIP Supplier rating system

- Incoming inspection

- In-process quality control

- On line Inspection

- Outgoing quality control

- Global RMA repair & management

- Customer quality management & service

- Customer complain handling

- OEM quality report

- NPI quality control

- SPC established & management

- CLCA management

- Quality improvement

- BPI project

- Line Stop

- On-going reliability